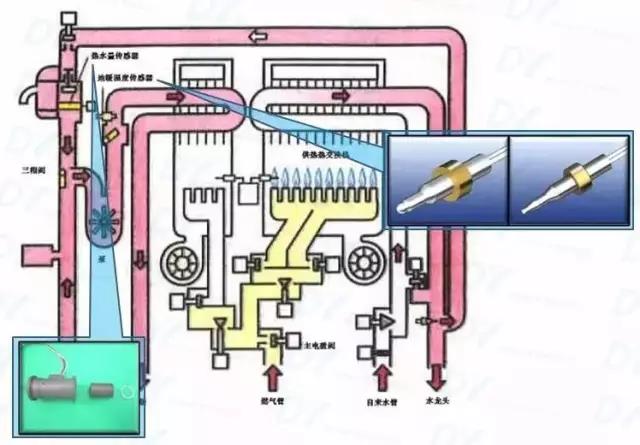

Today, we will introduce a fully automatic gas-fired wall mounted furnace, which can "heat" the kitchen and shower; at the same time, it can "automatically heat" the floor heating (bathtub) according to the set temperature, and maintain the temperature; in addition, it can "add combustion" to the floor heating (bathtub) according to the set temperature. It consists of two heat exchangers, control valves and pumps for gas and water. In addition, it is equipped with sensors to sense the temperature and quantity of hot water, and controls the overall action of the machine through 16 bit MCU.

The heat exchanger works to boil hot water. A copper tube with water passing through is laid on the burner, and a thin plate structure is installed to increase the surface area of the copper tube. In this way, after ignition, the burner can release 30000 kcal of heat at most (represented by No. 16 wall mounted furnace), and the water in the copper tube can be quickly transferred through the thin plate and instantly heated into hot water.

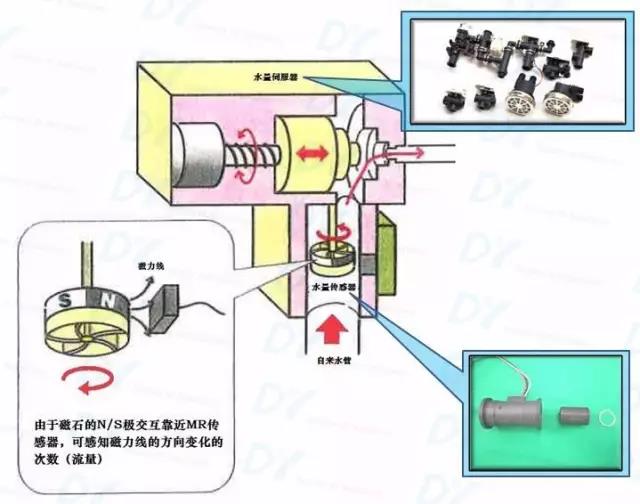

Now, we dissect the actual machine operation. First, when "heating", turn on the tap, and generate water flow in the wall hanging furnace, and the water sensor will perceive. In this way, the fan for combustion will start, the main solenoid valve will be opened, and the natural gas will be sent to the burner for combustion and hot water will be burned. At the same time, the water temperature sensor senses the hot water temperature, and sends the signal to the MCU. The MCU controls the hot water temperature by increasing and decreasing the water amount, the water volume server and the proportional valve of the gas quantity.

On the other hand, after the switch of "additional combustion" is turned on, the pump will start to suck the water from the floor heating (bathtub). The water flow switch senses the water flow, and it will ignite the burner of the floor heating heat exchanger, and the boiled water will be sent back to the floor heating (bathtub) again. When the set hot water temperature is reached, the floor heating (bathtub) temperature sensor will sense and stop the machine.

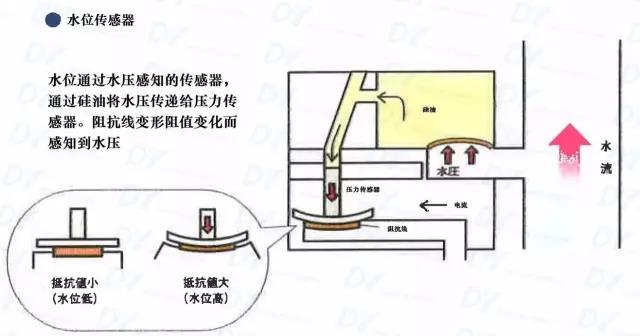

And "automatic heating", through the water injection solenoid valve, open to the floor heating (bathtub) water flow path, through the heating heat exchanger to deliver hot water. Then, the hot water quantity and water level are monitored by water quantity sensor and water level sensor, and the set quantity of hot water is injected. The temperature and water level of hot water can be automatically detected for a long time.

01

temperature control

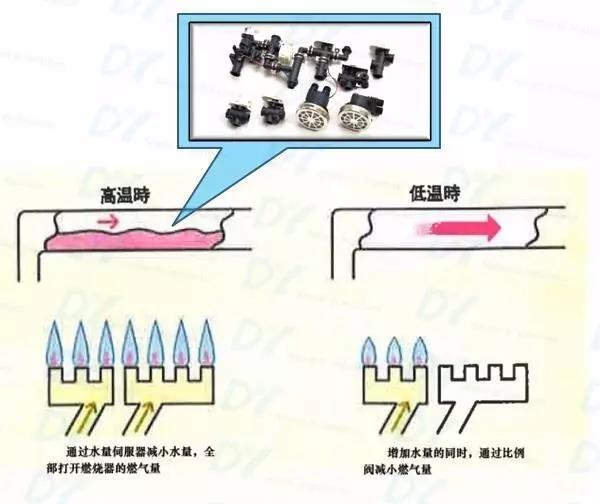

It's controlled by the water servo

The hot water temperature can be adjusted by controlling the water quantity in the copper tube of the heat exchanger and the firepower of the burner. When the temperature is expected to be higher, the flow path should be narrowed to make a small amount of water flow into the pipe slowly and absorb enough heat. On the contrary, when the temperature is expected to be lower, the flow path should be enlarged to make a large amount of water flow quickly. In addition, the proportion valve is used to control the amount of gas to regulate the firepower. When the hot water temperature is expected to be greatly reduced, the number of burners can be reduced by closing the switch valve.

[control by sensor sensing temperature]

图一

图一

图二

*Please contact us for specific product information

02

Single chip microcomputer control

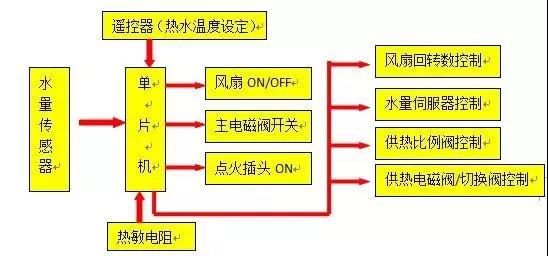

It is controlled by the combination of water sensor, thermistor and water server

The integral part of the automatic gas wall hanging furnace is a single chip microcomputer. For example, we observe the condition of "heating", and continuously start the fan, open the valve of main solenoid valve and power up the ignition plug by the MCU receiving the signal from the water sensor. Then, the water volume server, proportional valve and fan motor are controlled by comparing the signal of thermistor with the set temperature, and the water quantity, gas quantity and the number of fans rotation are calculated. Of course, the main parts are listed here, and the information volume processed by the single chip microcomputer will be more huge. Therefore, all such machines require 16 bit chips.

[control diagram]

*Please contact us for specific product information

03

Hot and cold water phenomenon

make a concrete analysis

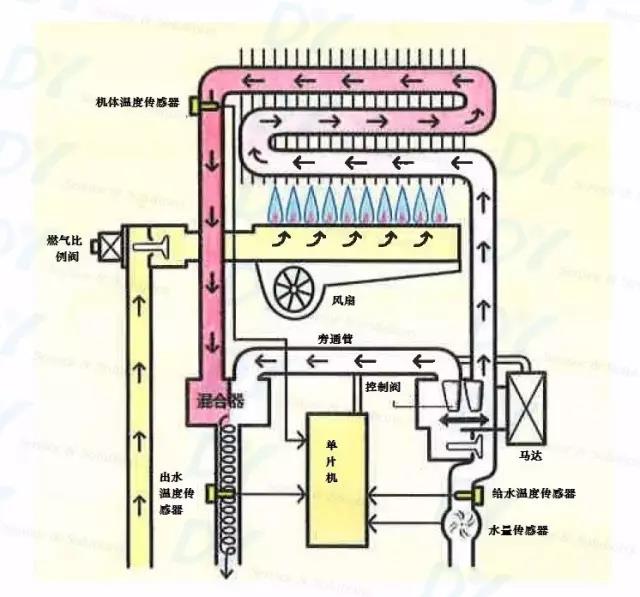

Cold and hot water phenomenon refers to the phenomenon that the temperature of hot water fluctuates sharply once the hot water stops and then flows out again. For example, when the water valve is turned off, the heat exchanger will be absorbed and hot water will be generated. The time difference between opening the water valve and the burner ignition will cause the phenomenon of continuous water outflow without heating.

Recently, in order to prevent this phenomenon, the bypass pipe with hot water and water mixture in the heat exchanger is designed. There is a valve for controlling the water quantity of the bypass pipe at the inlet. Based on the signal of three temperature sensors, the single chip microcomputer calculates the mixing ratio of the appropriate temperature and adjusts the opening of the valve at all times. This work will also be done when the water valve is closed. This allows the supply of hot water at the appropriate temperature at any time without time difference.

*Please contact us for specific product information

04

Safety device

make a concrete analysis

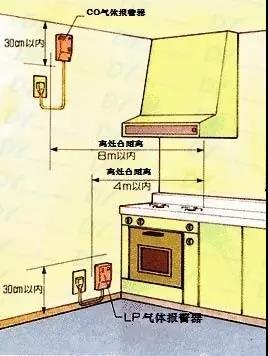

Incomplete combustion and gas leakage

When the gas is burned, it is necessary to mix with the air. The ratio is 1.5-1.6 for gas 1. If the air is below, it will produce incomplete combustion and CO poisoning. If it is higher than this ratio, the thermal efficiency will be worse.

There are also various kinds of gas, which can be roughly divided into three types: gas (low card gas), natural gas (high-level gas), liquefied petroleum gas (LP). However, there are more than ten kinds of low-carbon gas. At present, China has not fully realized the distribution of high-speed gas. Therefore, when we choose gas appliances, we need to distribute gas according to the residence to choose the suitable gas appliances. CO alarm and gas leakage alarm (CH4, LPG) are provided for safety.

CH4 alarm

installation diagram

installation diagram